论文总字数:25024字

摘 要

目前,压阻式压力传感器是压力测量中最常用的传感器。它具有体积小、稳定性高、频率响应快、易于集成化等特点,在航空航天、石油化工、生物医学、地震测量等领域应用的十分广泛。相信随着微电子技术和计算机的不断发展,压阻式压力传感器将在更多的领域内发挥着重大的作用。因此,我们有必要去了解它。压阻式压力传感器的工作原理是基于单晶硅或多晶硅的压阻效应,当材料受到外力作用时,载流子的迁移率发生了变化,导致了电阻的变化,从而引起了电阻率的变化。由于半导体材料对温度有较高的灵敏性,因此压阻式压力传感器的输出不可避免的受到温度的影响,产生了温度漂移。温度漂移极大的影响了传感器的精度和稳定性,温度漂移包含零点漂移和灵敏度漂移,这是半导体的物理性质对温度的敏感性决定的。温度漂移的补偿一般分为硬件补偿和软件补偿,硬件补偿主要采用结构对称的方式进行补偿,软件补偿能达到较高的补偿精度,可实现数字电路高准确度、线性化。本文通过建立数学物理模型,分析了压阻式压力传感器的温度漂移行为,着重分析了传感器的温度系数和压阻系数的影响,推导出了传感器的输出与温度、压阻系数的公式。

关键字:传感器,压阻效应,温度漂移,温度,压阻系数,补偿

ANAIYSIS AND CALIBRATION TECHNOLOGY PIEZORESISTIVE PRESSURE SENSOR DRIFT COMPENSATION MODEL

Abstract

Currently, piezoresistive pressure sensor is a pressure sensor measuring the most commonly used. It has small size, high stability, frequency response fast, easy integration and other characteristics, in the fields of aerospace, petrochemical, biomedical, seismic surveys and other applications are very wide. with the continuous development of microelectronics and computer technology, piezoresistive pressure sensors will play a significant role in many areas. Therefore, we need to understand it. It works piezoresistive pressure sensor is based on single-crystal or polycrystalline silicon piezoresistive effect, when the material is subjected to an external force, the carrier mobility changes, resulting in a change in resistance, causing a change in resistivity . Since the semiconductor material has a higher temperature sensitivity, so the output of piezoresistive pressure sensors inevitably affected by temperature, resulting in a temperature drift. Temperature drift greatly affect the precision and stability of the sensor, temperature drift contain zero drift and sensitivity drift, which is the physical properties of semiconductor sensitivity of the decision to temperature. Compensate for temperature drift compensation is generally divided into hardware and software compensation, hardware compensation structure mainly symmetrical manner to compensate, software compensation can achieve high compensation accuracy, digital circuitry high accuracy and linearization. Through mathematical physics model, the temperature piezoresistive pressure sensor drift behavior, analyzes the effect of temperature coefficient and piezoresistive sensors coefficient derived formulas and temperature sensor output, piezoresistive coefficient.

KEY WORDS: sensor, pizoresistive, temperature drift, temperature, pizoresistive coefficient, compensation

目 录

摘要·········································································Ⅰ

Abstract·····································································Ⅱ

- 绪论······························································· ···3

1.1压力传感器的发展现状·················································3

1.1.1压力传感器的发展历史············································3

1.1.2压力传感器的研究现状··································3

1.2 压力传感器的发展方向·······························4

1.3压力传感器的工作原理··································5

1.4压力传感器的性能指标····································5

1.5研究温漂补偿的意义·······························7

1.6主要研究内容及方法····································8

- 压力传感器的温漂补偿方法······································9

2.1硬件补偿·················································9

2.1.1片内补偿···································9

2.1.2片外补偿······································10

2.2软件补偿··········································11

- 压力传感器的温漂特性分析·································14

3.1温度特性············································14

3.2压阻特性··············································15

第四章 实验研究内容··········································20

4.1温漂模型的建立················································20

4.1.1电阻温度系数对输出的影响···························20

4.1.2压阻系数对输出的影响··································23

4.2数据的拟合和标定····················································23

第五章 总结与展望·····················································27

5.1研究工作总结················································27

5.2结论························································27

致谢 ··································································28

参考文献(References) ························································29

- 绪论

1.1压力传感器的发展现状

1.1.1压力传感器的发展历史

半导体传感器是现代压力传感器的重要组成部分,而半导体传感器大致可以分为一下四个阶段:

- 发明阶段(1945-1960年):在20世纪40年代,第一个双极性晶体管诞生了,这种特性的晶体管由于性能良好而得到了广泛的应用。史密斯Smith先生在这一年里发现了锗与硅的压阻效应。所谓的压阻效应就是当半导体材料受到外力的作用时,它的电阻将会发生明显的变化,电阻率也会发生很大的变化。根据这一原理制成的压力传感器是在金属薄膜上粘上应变电阻片,这个电阻片就可以把力信号通过电信号的形式表现出来。此阶段最小尺寸大约为1cm。

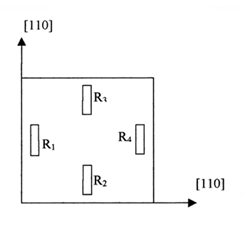

- 技术发展阶段(1960 - 1970年):经过科学家们对硅扩散的不断研究,硅扩散技术得到了迅速的发展。在半导体的晶向中,(001)和(110)晶向对压力传感器的性能较好,我们将应变电阻直接扩散在这晶面上,接着在背面凹形处进行加工,其中相对薄的弹性膜,称为硅杯。这种形式的压阻式压力传感器具有占用空间小、重量轻,因此能够大型的集成化,集成精度也提高了,灵敏度高、稳定性好,提高了传感器的性能,能够测量更微小的压力变化,成本低廉,可以大规模的生产,使得金属--硅共晶体的的大规模生产成为了可能。

- 大规模集成加工阶段(1970-1980年):以硅杯扩散理论为基础,通过使用硅各项异性蚀刻技术,扩散硅传感器的加工工艺得到了提高。该各项异性硅薄膜-硅技术,主要有V型槽法、硼浓度自动终止法、悬挂的阳极氧化法和计算机控制自动终止法。因为可以在多个表面进行腐蚀,所以成千上万的硅压力薄膜可以同时生产出来,这样就可以大规模的进行加工生产,降低了生产成本,提高了生产效率,实现了集成化的生产加工模式。

- 微机械加工阶段(1980 年- 今):微机械加工工艺由于上世纪末出现的纳米加工工艺成为了可能。利用微机械加工工艺,在计算机的精确操控下,我们能够制造出这一类压力传感器,结构型的,该传感器的尺寸是微米级的,如此小的传感器能够运用到纳米级的电子元器件中。这项加工工艺拉开了压力传感器微米级的阶段。

1.1.2压力传感器的研究现状

压力传感器主要经过了以下四种发展阶段:

- 光纤压力传感器

这类光纤传感器的研究成果十分广泛,但是在实际领域的运用并不是很多。其工作原理是:对压力敏感的元件在压力的作用下,发生了形变,那么当光照射在这个元件上时,光的化学性质(如光的强度、波长、频率、相位等)就发生了变化,将改变之后的光经过光纤送入光探测器中,通过检测光强、波长、频率或相位的微小的变化,来测得压力的大小。这种敏感元件在临床医学上被用来测扩张冠状。这种传感器灵敏度较高,可在高温高压等恶劣环境中工作,但是制作成本也相应的提高了。

- 电容式压力传感器

电容式压力传感器是由一块基片和氧化铝(Al2O3)构成,自熔焊接圆环钎焊在它们的中间。该环具有隔离作用,它不需要进行温度补偿,就能保持长期的可靠性和精确测量的耐用性。利用电容原理进行测量,基片上有两个电容,一个在位移最大的膜片的中央,另一个参考电容在膜片的边缘。因为电容在边缘处,基本上是固定不动的,所以很难产生位移,电容的板间距基本上没发生变化,电容大小就不会发生变化,CP的变化主要大部分来源于压力的变化,我们知道,外界压力的变化会导致膜片的位移量发生变化,它们之间的关系是线性的一对一的关系。在外界压力太大时,达到了电容式压力传感器的承受极限时,贴在基片上的膜片由于自我保护,是不会被破坏的,在没有压力的时候膜片会立刻回到原来的位置,不会产生任何的滞后,过载能力达到100%,如果由于其它的因素,传感器遭到破坏,是不会泄露任何的污染环境的化学物质的。因此这类传感器具有广泛的应用前景。

(3)微机械加工传感器

剩余内容已隐藏,请支付后下载全文,论文总字数:25024字

相关图片展示: