论文总字数:29110字

摘 要

的表面织构刀具对钛合金进行切削加工,得出切削温度和切削力的结果,另外还有一组基础参照,即普通刀具切削钛合金的切削温度和切削力的结果,进行分析对比,得出结论。研究结果表面,本文所重点研究的ST-3型表面织构不会发生次生切削,在此种情况下,表面织构能够减小刀屑直接接触面积,减磨,从而降低切削力和切削温度,并且得出具有ST-3型表面织构的刀具最优的槽宽尺寸范围在20-40 之间。而ST-3型表面织构在理论上来说是可能发生次生切削的,至于为何没有发生次生切削,本文在第三章的3.4节将其与另外两种发生了次生切削的表面织构进行了结构设计上面的对比,得出结论是因其槽的V字型较为平缓,切屑更容易流出,并不像另外两种织构那样槽深陡且延展较长。本文的创新点是对于ST-3型表面织构的研究属于前列,国内外目前对此种织构研究的非常少,在一定程度上,本文为以后的学者研究提供了一定的基础参考以及研究思路。

之间。而ST-3型表面织构在理论上来说是可能发生次生切削的,至于为何没有发生次生切削,本文在第三章的3.4节将其与另外两种发生了次生切削的表面织构进行了结构设计上面的对比,得出结论是因其槽的V字型较为平缓,切屑更容易流出,并不像另外两种织构那样槽深陡且延展较长。本文的创新点是对于ST-3型表面织构的研究属于前列,国内外目前对此种织构研究的非常少,在一定程度上,本文为以后的学者研究提供了一定的基础参考以及研究思路。关键词:表面织构;DEFORM-3D;次生切削;切削温度;切削力

The optimization of surface texture of cutting tool based on the secondary cutting theory

02611206 xuhuan

Supervised by wuze

Abstract: This paper mainly reseraches different texture parameters of surface texture tool cutting of titanium alloy, to observe the secondary cutting if it happens, how to reduce and avoid the secondary cutting, in both cases of stress concentration, to find the optimal texture parameters, processing parameters reference for practical production.Focused on the surface texture size analysis, to explore, find out the most suitable texture size, the maximum extent, improve the cutting performance of the cutting tool. In this paper, the method is adopted mainly adopts the simulation experiment and contrast method, by using DEFORM-3D software simulation of surface texture tool cutting titanium alloy cutting experiment. Mainly adopt the method of the groove width as a variable, groove width size of 20, 40, 60, 80 respectively, the surface texture of cutting tools for machining titanium alloy, it is concluded that the results of cutting temperature and cutting force, plus a set of basic reference, namely ordinary cutter cutting of titanium alloy cutting temperature and cutting force as a result, the contrast analysis, draw the conclusion. Surface of the research results, this paper focuses on the ST-3 secondary cutting, surface texture is not going to happen in such a case, the surface texture crumbs directly contact area can reduce the knife and antifriction, so as to reduce the cutting force and cutting temperature, and it is concluded that with ST -3 surface texture tool optimal groove width size range from 20 to 40. And ST -3 surface texture in theory is possible secondary cutting, why no secondary cutting, section 3.4 in the third chapter in this paper with the other two secondary cutting surface texture of the structure design of the above comparison, the conclusion is because of its groove V is relatively flat, chip flow more easily, does not like the other two texture slot depth steep and extension is longer than the other. The innovation of this article is for ST-3surface texture research belongs to the top, both at home and abroad at present this kind of texture research is very little, to a certain extent, this article for later study provides a certain reference and the basis of the research train of thought.

respectively, the surface texture of cutting tools for machining titanium alloy, it is concluded that the results of cutting temperature and cutting force, plus a set of basic reference, namely ordinary cutter cutting of titanium alloy cutting temperature and cutting force as a result, the contrast analysis, draw the conclusion. Surface of the research results, this paper focuses on the ST-3 secondary cutting, surface texture is not going to happen in such a case, the surface texture crumbs directly contact area can reduce the knife and antifriction, so as to reduce the cutting force and cutting temperature, and it is concluded that with ST -3 surface texture tool optimal groove width size range from 20 to 40. And ST -3 surface texture in theory is possible secondary cutting, why no secondary cutting, section 3.4 in the third chapter in this paper with the other two secondary cutting surface texture of the structure design of the above comparison, the conclusion is because of its groove V is relatively flat, chip flow more easily, does not like the other two texture slot depth steep and extension is longer than the other. The innovation of this article is for ST-3surface texture research belongs to the top, both at home and abroad at present this kind of texture research is very little, to a certain extent, this article for later study provides a certain reference and the basis of the research train of thought.

Key words: surface texture;DEFORM-3D;secondary cutting;cutting temperature;cutting force

目录

摘要.................................................................................................................................................. I

关键词................................................................................................................................................I

Abstract............................................................................................................................................II

Key words.........................................................................................................................................II

- 绪论.................................................................................................................................................1

1.1课题研究背景及意义..............................................................................................................1

1.2国内外研究概况......................................................................................................................1

1.2.1表面织构刀具的研究现状.............................................................................................1

1.2.2表面织构刀具的概念.....................................................................................................2

1.2.3表面织构加工技术.........................................................................................................2

1.2.4表面织构刀具的发展.....................................................................................................3

- 切削仿真过程建模.........................................................................................................................5

2.1有限元分析的基本思想..........................................................................................................5

2.1.1有限元分析的基本过程.................................................................................................5

2.1.2DEFORM-3D软件的介绍..............................................................................................5

2.1.3DEFORM-3D软件的模块结构......................................................................................5

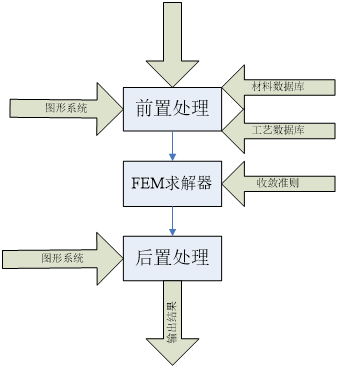

2.1.4DEFORM03D软件操作流程..........................................................................................6

2.2几何模型..................................................................................................................................6

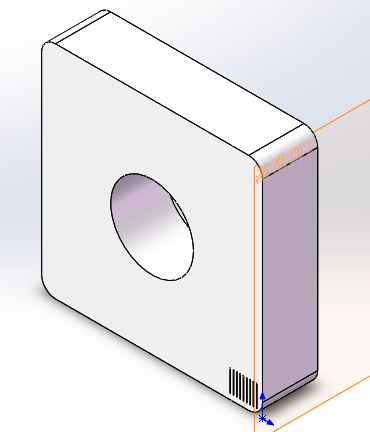

2.2.1刀具几何模型.................................................................................................................6

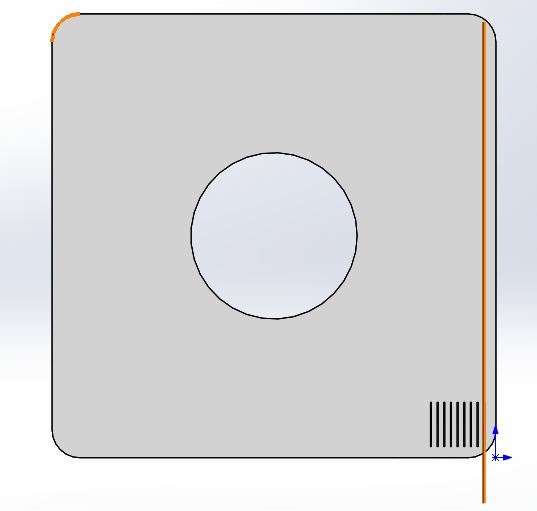

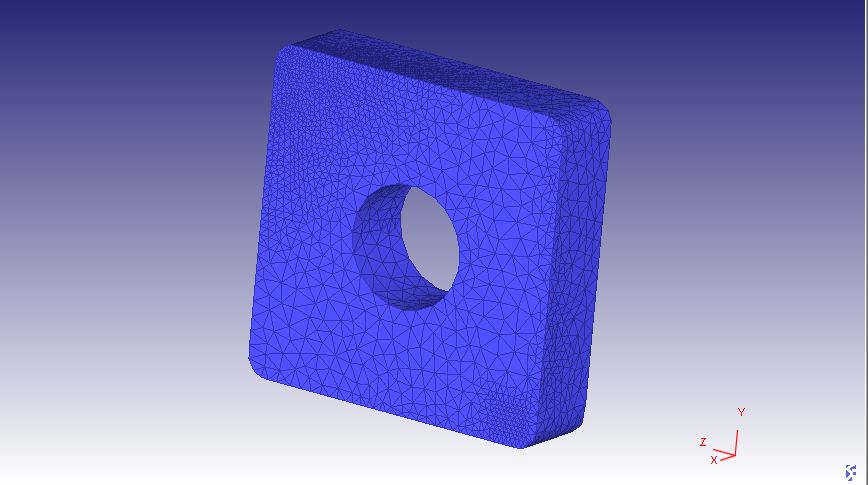

2.2.2工件几何模型.................................................................................................................7

2.3物理模型..................................................................................................................................8

2.3.1刀具材料.........................................................................................................................8

2.3.1工件材料.........................................................................................................................8

2.4初始条件和边界条件..............................................................................................................8

2.4.1刀具切削模型的初始条件及边界条件.........................................................................8

2.5分析步的建立和网格的划分..................................................................................................8

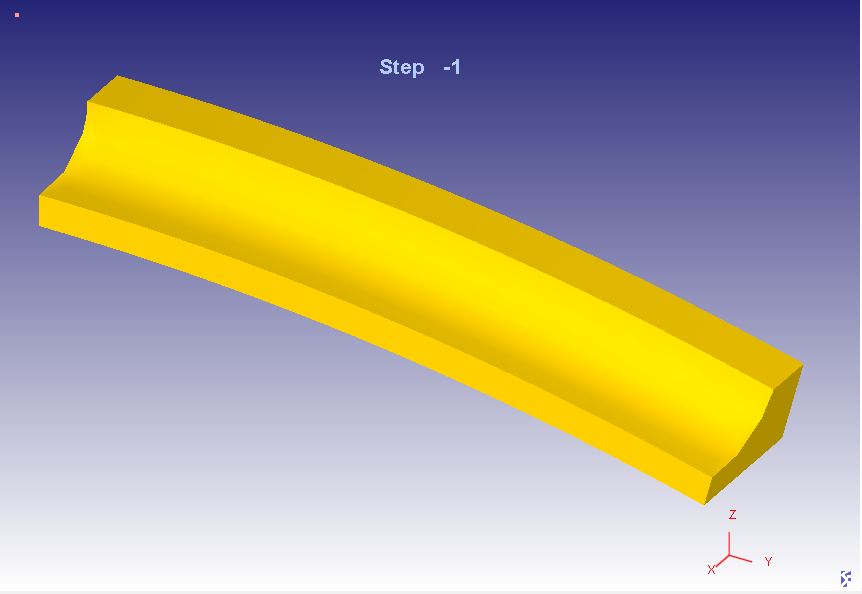

2.5.1分析步的建立.................................................................................................................9

2.5.2网格的划分.....................................................................................................................9

- 仿真结果分析...............................................................................................................................10

3.1切削仿真方法........................................................................................................................10

3.2刀具切削温度........................................................................................................................10

3.2.1切削温度的来源...........................................................................................................11

3.2.2切削温度的测量...........................................................................................................11

3.2.3切削温度的规律...........................................................................................................11

3.2.4切削温度的研究意义...................................................................................................11

3.2.5切削温度的研究现状...................................................................................................11

3.2.6切削仿真实验结果的切削温度分析...........................................................................11

3.3切削力....................................................................................................................................13

剩余内容已隐藏,请支付后下载全文,论文总字数:29110字

相关图片展示:

该课题毕业论文、开题报告、外文翻译、程序设计、图纸设计等资料可联系客服协助查找;